Foil lamination is an industrial process in which decorative foils are bonded to substrate materials in order to improve their appearance and feel. Foil lamination is particularly interesting for manufacturing companies, as the added value generated by this refinement process clearly exceeds the material and processing costs incurred. This means that a high-quality product can be produced with a good return on investment.

Wide product range

Film lamination is used in a wide variety of applications. Generally, a distinction is made between products for the EXTERIOR market, e.g., window profiles, entrance doors, sliding doors and conservatories, and products for the INTERIOR market: furniture (elements), interior doors and door frames, wall panelling, skirting boards, picture frames and many more.

Base materials

While products for outdoor use are mostly made of PVC and aluminium, products for indoor use are mostly based on wood and wood-based materials (MDF, HPL and chipboard). The common feature is the processing in the wrapping application. In this process, decorative foils are glued to the base materials using special adhesives to give them an attractive appearance and the desired surface structure.

Decorative materials

Windows and doors are usually laminated with specially developed PVC foils which, thanks to a particularly weather-resistant surface, can withstand extreme climatic conditions and sunlight for many years. The variety of colours has grown steadily over the years; today, customers have all options open to them, from wood decors to single-colour and metallised foils with high-gloss or supermatt finishes, in order to meet even the most unusual customer wishes. In the furniture industry, even more different decorative materials are used, from real wood veneers and laminates to paper and plastic foils. This means that there are no limits to product design.

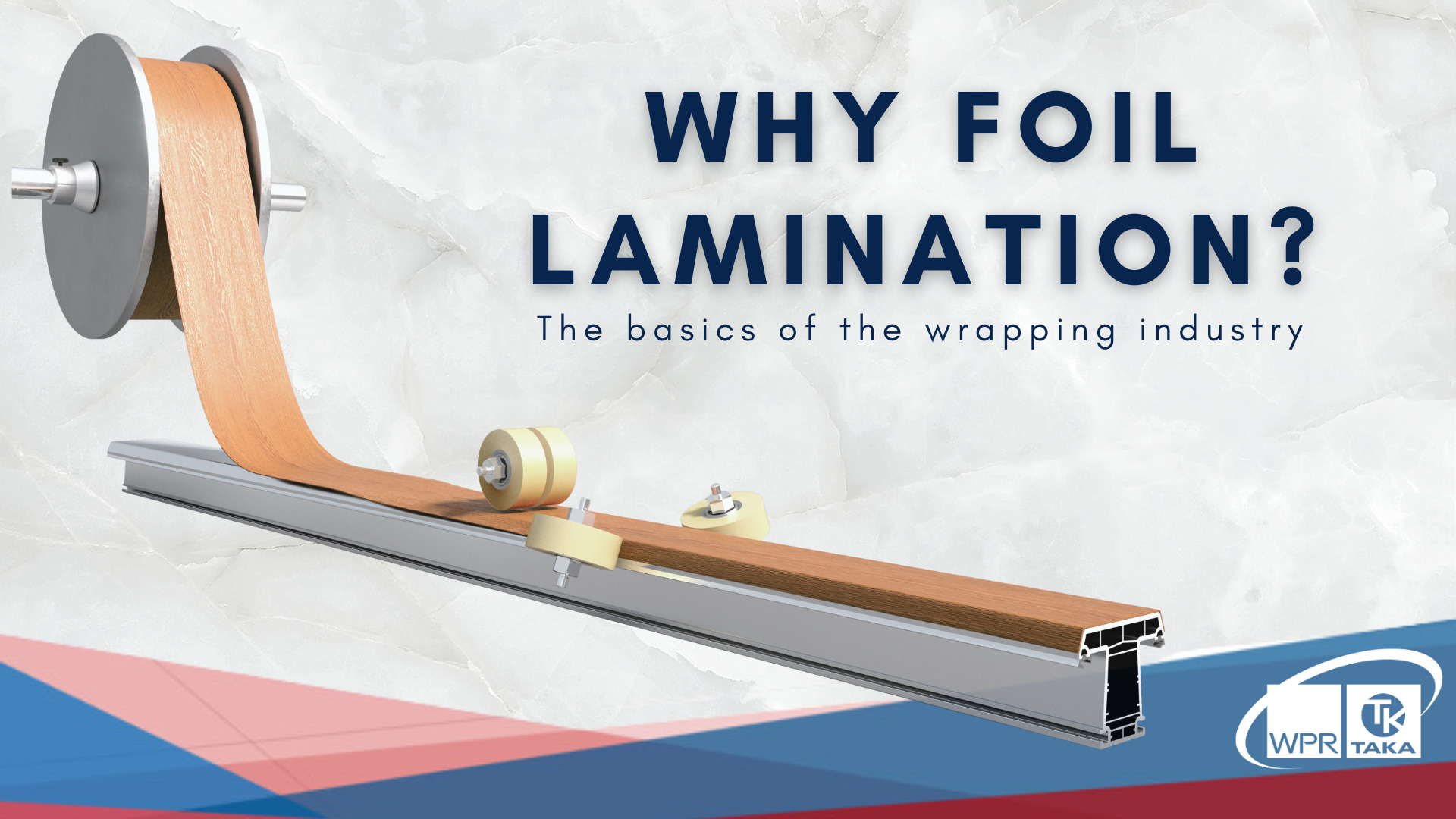

The advantages of the lamination process

Film lamination is already a well-established industrial process that has continuously evolved over the years. Film lamination is already a well-established industrial process that has continuously evolved over the years. In a linear and continuous process, the profile bars or panels are run through the lamination machine. Then the reactive polyurethane hot-melt adhesive is applied to the decorative foil, which is then bonded to the surface using a series of pressure rollers. The great advantage of foil lamination over other colouring processes, such as lacquering or co-extrusion, is the almost endless choice of surface decors and especially the fast changeover between decors. During the ongoing lamination process, different films and decors can be processed continuously, resulting in high productivity and low machine downtimes.

Contact

If you would like to know more about this relatively simple but highly efficient process of foil lamination, why not contact the experts in the industry now? Send us an email at [email protected]. WPR has been manufacturing high quality laminating equipment for over 20 years, while TAKA is the leading supplier of high-performance PUR hot melt adhesives. We offer our customers an “all-round carefree” service, as well as personalised trainings on how to set up competitive lamination department.