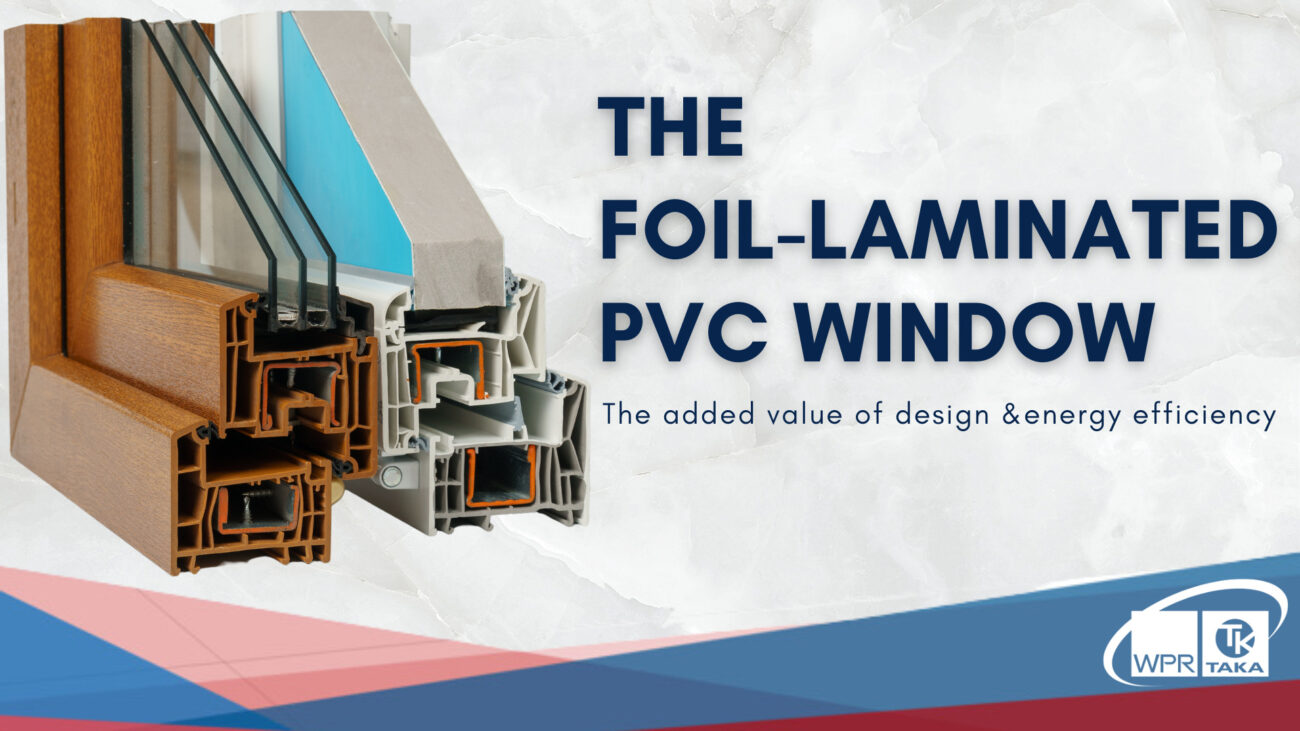

The world of PVC window laminated with decorative foil

For a long time, the PVC window was inferior to the dominant materials such as wood and aluminium. But not only since the emerging energy crisis has this high-tech product enjoyed ever greater popularity. Especially the large variety of colours and designs as well as the comparably low-price level make the foiled PVC window an affordable design product that also offers high energy efficiency.

High added value

For window manufacturers, foil lamination, i.e., the bonding of decorative PVC foils to the window profiles, offers great added value. On the one hand, it allows them to fulfil all their customers’ wishes and offer a wide range of products, but at the same time, foil lamination offers an economic added value that far exceeds the material and processing costs of lamination.

Thus, coloured windows can be sold far better as a trendy design object than the white PVC window, which still has the reputation of being an inferior product. In addition, the window foils are usually more colour-stable than untreated PVC, which can lose its colour fastness after years.

Wide variety of colours

In recent years, architects, designers and also private customers have increasingly opted for coloured windows. Thanks to the almost endless variety of colours and surface structures, windows can be completely tailored to the customer’s special wishes. For a long time, wood decors were the trend, but today it is mainly monochrome windows with a strong tendency towards dark shades of grey up to black, whereby matt surfaces are becoming increasingly popular.

The leading foil manufacturers are constantly expanding their product ranges and impressing with ever new wood and metal surfaces with a deceptively real feel. As a result, laminated PVC windows can hardly be distinguished from real wood windows from a distance, but also when touched.

Low maintenance and cleaning effort

Another great advantage of laminated PVC windows is the low maintenance and cleaning effort. While wooden windows in particular have to be repainted regularly, this is not necessary with laminated windows. Should the surface ever be damaged by knocks or scratches, they can be seamlessly repaired with special repair foils. Thus, coloured PVC windows have a very high life expectancy.

Energy efficiency

However, PVC windows offer another major advantage that has only come to the fore with the rapid rise in energy costs. Compared to other materials, they have the highest energy efficiency. Triple-glazed windows in particular prevent the loss of heat from the heating system in the cold winter and the penetration of outside heat in the summer, so that the living space is always kept at a comfortable temperature. Therefore, energy-efficient PVC windows are a worthwhile investment to reduce the energy consumption of a building in the long run.

Recycling

As already mentioned, PVC windows are a very durable product that can easily provide homeowners with 30 to 40 years or more of enjoyment At the end of its life cycle, the laminated window and window foil can be completely recycled by simply returning it to the production cycle. This means that the same PVC material can be recycled at least seven times, giving the product an extremely low energy footprint.

Contact

If you are a window manufacturer and would like to know more about this relatively simple but highly efficient foil lamination process, why not contact the industry experts now? WPR has been manufacturing high quality laminating equipment for over 20 years, while TAKA is the leading supplier of high-performance PUR hot melt adhesives. We offer our customers an “all-round carefree” service, as well as personalised training on how to set up competitive profile laminating.