They consist mainly of polyesters and isocyanates.

Also known as polyurethane hot melt adhesives, they are the only adhesives on the market that guarantee chemical on top of physical bonding. This is because once they are melted and applied, a chemical reaction, called cross-linking, will start in contact with air and moisture.

This chemical reaction then transforms hot melt adhesives into thermo-curing adhesives. This is an irreversible process that means that the glue can no longer become liquid again as soon as it has been melted and this lends to the laminated profile or panel:

As they cool down, they already develop a very high initial grip, which, among other advantages, enables a continuous, linear production process without the use of static pressing machines.

Polyurethane glues can be combined with an almost unlimited variety of materials, so we could almost refer to them as universal glues.

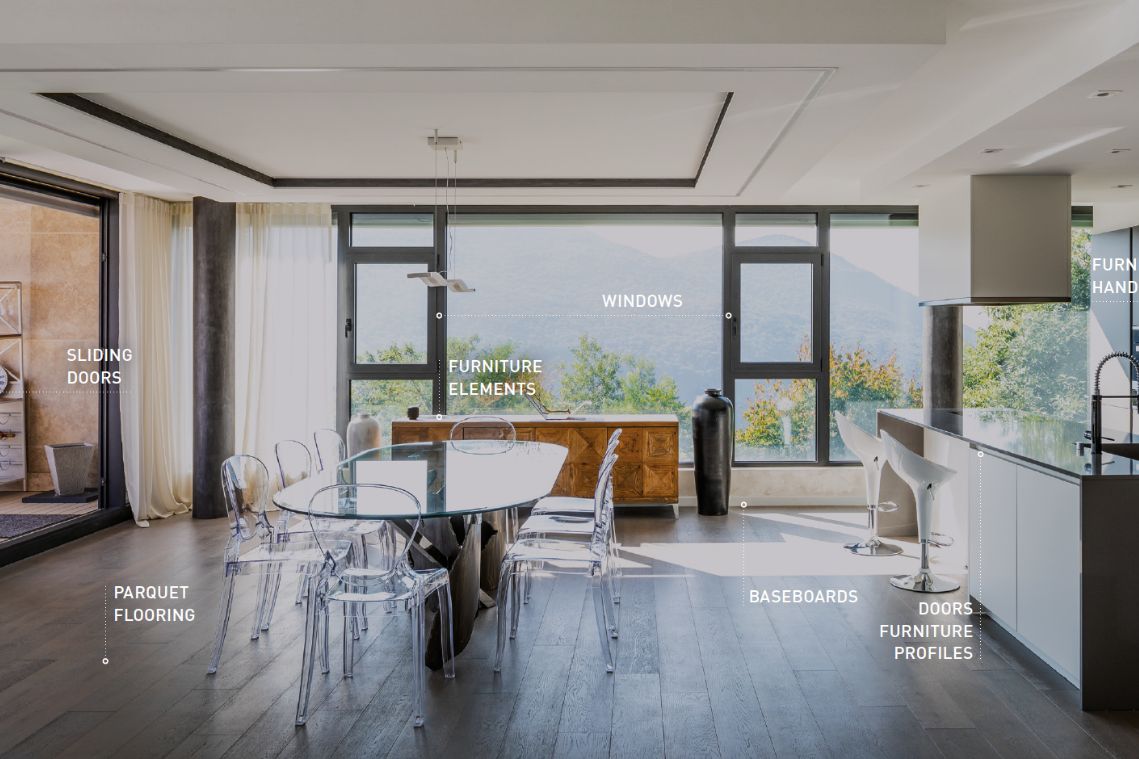

They find application in the automotive industry, window production and the textile, furniture and many other processes.

An important aspect of PUR hot melt adhesives is that after curing they are completely emission-free and do not release formaldehyde or other harmful substances. More and more manufacturers in the furniture industry have decided to use them.

In recent years, TAKA has invested in the production of adhesives that offer an increased work safety for users, hence the LESS line of hot melt adhesives with a monomer isocyanate content of less than 0.1%. These so-called ‘low-emission adhesives’ (or micro emission adhesives) are therefore not subject to the labelling requirements of the Ordinance on Hazardous Substances according to the European Regulation, thus contributing to the protection of workers in the production department.

TAKA is increasingly investing in the research of alternative raw materials to those of fossil origin. This results in the creation of a range of bio-based adhesives that guarantee an adhesive performance in line with standard TAKA adhesives. These polyurethane adhesives have a high percentage of materials derived from bio-based sources (such as maize, sugar cane or cellulose).

HMPUR polyurethane glues offer a cost-efficient choice in terms of application weights and performance. Compared to EVA- or PO-based glues, the average HMPUR glue consumption is 30-50% lower, while offering far superior performance.