There are three types of primer on the market: those with MEK-based solvent (flammable), those with DCN-based solvent (non flammable) and those with little or no VOCs.

The length of the machine (specifically, the distance between the primer application area and the pressing roll) should be taken into account when choosing the primer. For traditional primers (MEK- or DCN-based) the length of the primer application area should be 1.5-2 metres; for environmental-friendly primers (low or 0% VOCs), instead, the length should be no shorter than 3.5 metres.

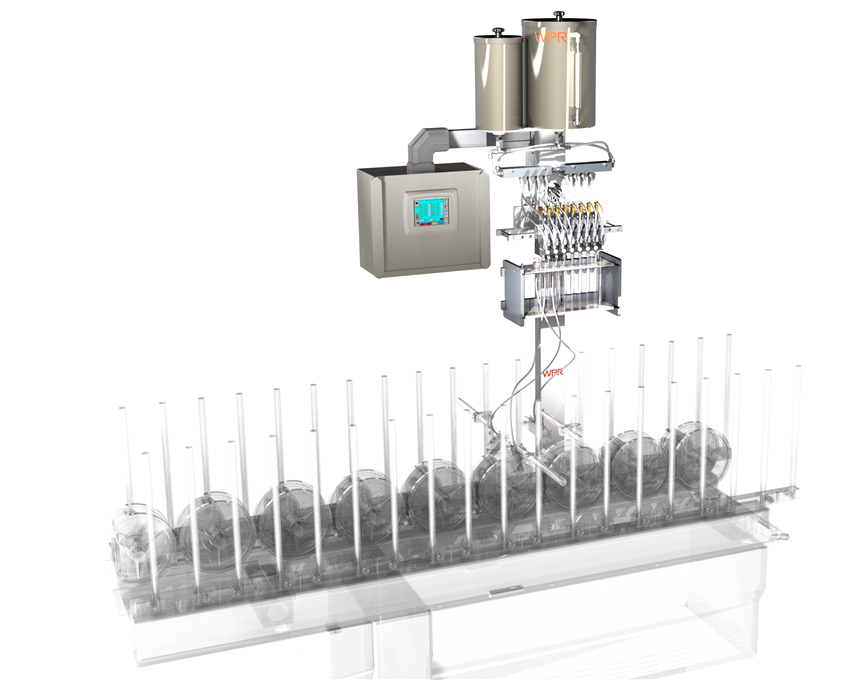

When using environmental-friendly primers, the application must be performed by means of an automatic dosing system, so as to guarantee their correct application, as the dose is too low (6-10g/m2), and to avoid delaying the drying of the primer itself.

Another important aspect of primer application is the environment temperature, which should not be lower than 18°C. When the profile temperature is too low, in winter, for instance, heating the profile to 18-25°C is recommended.

Primer drying area and profile heating:

A distance of 0.5 metres between the primer application area and the drying area is recommended for traditional primers, while for environmental-friendly ones the distance should be 1 metre (this is to allow the primer to soak the profile). The primer must be completely dry to avoid the formation of bubbles between the profile and the foil.

Before proceeding with the pressing phase, the profile must be pre-heated with IR lamps or air heaters to a temperature between 45° and 55°C, so that the adhesive finds the best environment for physical adhesion.